The Dangers of Single Strand Aluminum Wire in Your Home

I’m not sure if you have an area as we do in South Florida that has a ton of homes with single strandtrand aluminum wire installed, but I haven’t seen one of those homes not having an issue being insured. Single strand aluminum wires used for residential electrical application has been deemed unsafe.

Single strand aluminum wiring refers to electrical wiring made from a single strand of aluminum instead of multiple strands or a bundle of strands. It is commonly used in residential, commercial, and industrial electrical applications. Single strand aluminum wire is lightweight, corrosion-resistant, and relatively inexpensive compared to other types of wire, making it an attractive option for some electrical installations.

Aluminum wiring is not banned, but it has been largely replaced by copper wiring in many countries due to safety concerns. The use of aluminum wiring in residential electrical systems became popular in the 1960s and 1970s due to its lower cost and lighter weight compared to copper. However, it was later discovered that aluminum wiring can be more prone to overheating and other problems, which can increase the risk of electrical fires.

Single Strand Aluminum Wire Hazards

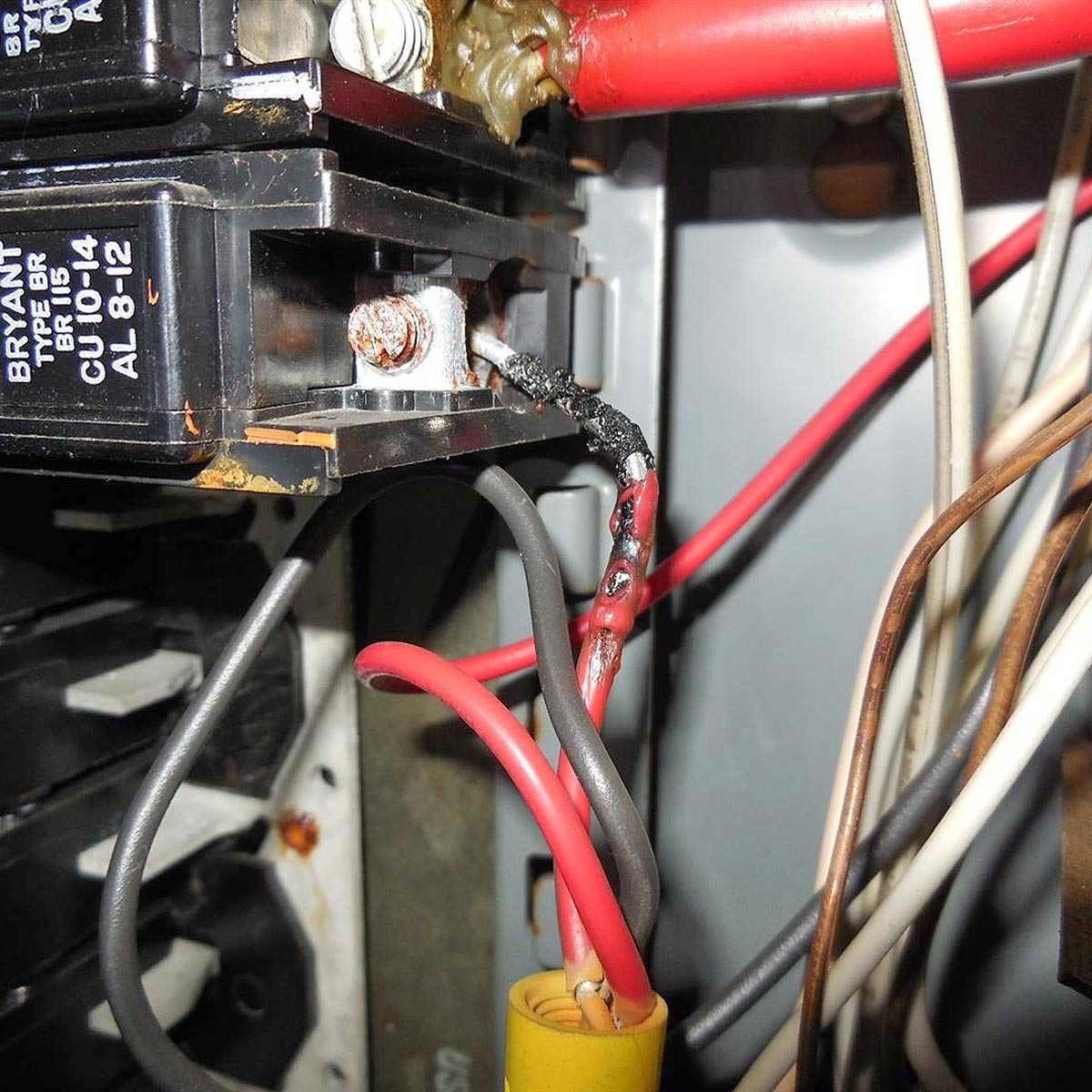

- Overheating: Single strand aluminum wire has a higher electrical resistance compared to copper wire, which can cause overheating and increase the risk of electrical fires.

- Joint corrosion: Joints in single strand aluminum wiring are prone to corrosion, which can cause electrical failure and increase the risk of fire.

- Loosening of connections: Over time, the connections between the wire and electrical devices can loosen, leading to arcing and overheating.

- Difficulty with maintenance and repairs: Single strand aluminum wire can be difficult to work with and repair, which can make it challenging to maintain electrical systems and resolve problems.

- Lack of compatibility: Single strand aluminum wire may not be compatible with some electrical devices, fixtures, and wiring systems, leading to a higher risk of fire and other hazards.

- Reduced conductivity: Single strand aluminum wire has a lower conductivity than copper wire, which can limit the amount of electrical power carried through the wire and lead to reduced efficiency.

In response to these concerns, many countries have adopted stricter building codes and standards that require the use of copper wire in residential electrical systems. In some cases, homes with aluminum wiring may be required to be retrofitted with copper wire to meet these standards.

Types of Aluminum Wire

There are several aluminum wires used in electrical applications, including:

- Solid Aluminum Wire: Solid aluminum wire is a single-strand of aluminum wire with no insulation, typically used in overhead electrical applications, such as overhead power lines.

- Stranded Aluminum Wire: refers to a bundle of multiple strands of aluminum wire used together to carry electrical current. This type of wire is commonly used in residential electrical systems and is more flexible and easier to work with than solid aluminum wire.

- Aluminum-Clad Steel Wire (ACSR): Aluminum-clad steel wire is a composite wire made of a core of steel wire surrounded by a layer of aluminum. This type of wire is commonly used in overhead electrical applications, as it provides the strength of steel with the electrical conductivity of aluminum.

- Aluminum Building Wire: Aluminum building wire is a type of electrical wire used in residential and commercial buildings. It is made of multiple strands of aluminum wire and is designed to be flexible and easy to install.

- Aluminum Service Entrance Wire: Aluminum service entrance wire is a type of electrical wire used to bring electrical power into a building. It is made of multiple strands of aluminum wire and is designed to be flexible and easy to install.

Each type of wire has its own unique properties and is suited for different applications. When selecting aluminum wire for a specific electrical application, it’s important to consider factors such as electrical conductivity, resistance to overheating, and compatibility with electrical devices and fixtures.

What is the difference between single and multi strand aluminum wiring?

Single-strand aluminum wire and multi-strand aluminum wire refer to the number of strands of aluminum wire used in an electrical circuit.

Single strand aluminum wire refers to a single strand of aluminum wire that is used as a conductor to carry electrical current. This type of wiring is commonly used in overhead electrical applications, such as overhead power lines and in electrical wiring for commercial and industrial applications.

Multi-strand aluminum wire, on the other hand, refers to a bundle of multiple strands of aluminum wire used together to carry electrical current. This type of wiring is commonly used in residential electrical systems, as it is more flexible and easier to work with than single strand aluminum wire.

In terms of performance, multi-strand aluminum wire is generally considered to be safer and more reliable than single strand aluminum wire. This is because the multiple strands in a bundle of multi-strand aluminum wire help to reduce the resistance of the wire and reduce the risk of overheating, which can be a major safety concern with single strand aluminum wire.

How to Fix Single Strand Aluminum Wiring

If you have single strand aluminum wiring in your home and are concerned about its safety, here are some steps you can take to help address the issue:

- Hire a licensed electrician: A licensed electrician is trained to safely and correctly install, maintain, and repair electrical systems. They can assess your electrical system and determine the best course of action to address any potential safety concerns.

- Install Aluminum-to-Copper Connectors: Aluminum-to-copper connectors are devices that are specifically designed to join aluminum and copper wire. If you have aluminum wiring in your home, these connectors can be used to join the aluminum wire to copper devices, such as outlets and switches, in a way that reduces the risk of overheating and other safety hazards.

- Re-wire the electrical system: If your electrical system has extensive safety concerns, re-wiring the system with copper wire may be necessary. This is a complex and time-consuming process that should only be performed by a licensed electrician.

- Upgrade electrical devices and fixtures: Upgrading electrical devices and fixtures to those that are specifically designed for use with aluminum wire can also help to reduce the risk of overheating and other safety hazards.

I hope this blog article has been helpful. If you have additional questions and want to get in contact with GGR Home Inspections please send us a note, text, or call.

Related Article

Truth Behind Aluminum Wiring (2023 Guide)

Pingback: 4 Point Inspection, What No One Tells You. Read This Today

Pingback: Shop for a Home with these 4 Major Components in Mind - GGR Home Inspections

Pingback: Learn What 50 AMP Wire Size For a 50 Amp Breaker (2023 Guide) – GGR Home Inspections