Understanding 40 AMP Wire Size:

Importance, Guidelines, and Installation Tips

Understanding the 40 AMP wire size is essential for both safety and efficiency. It’s not just about getting power from point A to point B. It’s also about making sure that the wire can handle the load without overheating or causing a fire hazard. In this article, we’ll delve into the ins and outs of 40 AMP wire size. You’ll learn what it is, why it’s important, and how to choose the right wire size for your specific needs. From homeowners to electricians, this information could be useful to anyone dealing with electrical installations or repairs. So, let’s get started and shed some light on this important topic.

What is 40 AMP Wire Size?

Understanding Wire Sizes and Ampacity

In the world of electrical wiring, choose the right wire size to ensure the safe and efficient operation of your circuits. Wire size is determined by its gauge, which refers to the diameter of the wire. The smaller the gauge number, the thicker the wire.

One important factor to consider when selecting wire size is ampacity, which is the maximum current a wire can safely carry without overheating. Ampacity varies depending on the wire size and insulation type. Exceeding the ampacity of a wire can lead to overheating, which can cause electrical fires and damage to your electrical system.

Importance of Choosing the Right Wire Size for 40 AMP Circuits

When it comes to 40 AMP circuits, selecting the appropriate wire size. Using wire that is too small may lead to overheating, while wire that is too large can be unnecessary and costly. Here’s why choosing the right wire size is important for 40 AMP circuits:

- Safety: Selecting the correct wire size ensures that the wire can handle the current flowing through the circuit without overheating. This reduces the risk of electrical fires and ensures the safety of your home or business.

- Efficiency: Using the appropriate wire size minimizes voltage drop, which is the decrease in voltage as current flows through the wire. Voltage drop can lead to inefficient operation of your electrical devices and can cause them to malfunction or not perform optimally.

- Compliance: Following electrical codes and regulations is essential to ensure the safety and legality of your electrical installations. Choosing the right wire size for 40 AMP circuits ensures that you meet the requirements set forth by these codes and regulations.

- Cost-effectiveness: Using the correct wire size for 40 AMP circuits avoids unnecessary expenses. Oversized wire can be more expensive and may require larger conduit or junction boxes. By choosing the appropriate wire size, you can optimize your electrical system while keeping costs in check.

To determine the right wire size for your 40 AMP circuit, it is recommended to consult the National Electrical Code (NEC) and local electrical regulations. These guidelines provide specific ampacity ratings for different wire sizes and insulation types, ensuring that your electrical system operates safely and efficiently.

Factors to Consider for 40 AMP Wire Size

When it comes to electrical installations, choosing the correct wire size to ensure safety and optimal performance. In this section, we will delve into the key factors that need to be considered when determining the appropriate wire size for a 40 AMP circuit. These factors include the length of the circuit, material and type of wire, as well as temperature and ambient conditions.

Length of the Circuit

The length of the circuit plays a significant role in determining the appropriate wire size for a 40 AMP load. As the distance between the power source and the destination increases, so does the resistance in the wire. This resistance can lead to voltage drop, which can result in inefficient and unreliable electrical operation.

To minimize voltage drop, select a wire size that can compensate for the length of the circuit. Longer circuits typically require larger wire sizes to ensure that an adequate amount of power reaches the intended destination without significant voltage loss.

Material and Type of Wire

The material and type of wire chosen for a 40 AMP circuit is another essential consideration. Different materials have varying conductivity levels, which can affect the overall performance of the electrical system.

Copper is a widely used material for electrical wiring due to its excellent conductivity. It offers low resistance and allows for efficient power transmission. On the other hand, aluminum wire, although less conductive than copper, can still be used for certain applications. It is essential to consult local codes and regulations to determine whether aluminum wiring is permissible and what specific guidelines should be followed.

Temperature and Ambient Conditions

Temperature and ambient conditions can greatly impact the performance and safety of an electrical system. High temperatures can cause wire insulation to deteriorate, potentially leading to short circuits or other electrical hazards. In contrast, extremely low temperatures can make the wire more brittle, increasing the risk of damage and potential failure.

When selecting the wire size for a 40 AMP circuit, consider the expected temperature range and ambient conditions of the installation environment. This information will help determine the appropriate wire gauge and insulation type that can withstand the anticipated conditions, ensuring the longevity and reliability of the electrical system.

Calculating the Proper Wire Size for 40 AMP Circuits

When it comes to electrical wiring, select the right wire size for the specific circuit requirements. In this section, we will explore the National Electrical Code (NEC) guidelines and the use of wire size calculators to determine the appropriate wire size for 40 AMP circuits.

National Electrical Code (NEC) Guidelines

The NEC provides essential standards and guidelines for electrical installations across the United States. These guidelines ensure safety, efficiency, and consistency in electrical systems. When it comes to wire sizing, the NEC provides specific rules to follow.

One such rule is found in NEC Article 210, which states that conductors for branch circuits must have a capacity that exceeds the maximum load of the circuit. For a 40 AMP circuit, the wire size must be capable of handling the current safely without overheating.

To determine the proper wire size, you may refer to NEC Table 310.15(B)(16). This table provides the ampacity ratings for different wire sizes based on the type of insulation and the installation method. The ampacity rating indicates the maximum current a wire can safely carry.

When selecting a wire size, it’s essential to choose one that meets or exceeds the ampacity requirements for a 40 AMP circuit. This ensures that the wire can handle the current flow without posing a safety hazard.

Using the Wire Size Calculator

Calculating the wire size manually can be a complex task, especially for those who are not familiar with electrical calculations. Fortunately, online tools, called wire size calculators, simplify the process.

Wire size calculators take into account various factors such as the circuit’s voltage, amperage, length, and material to determine the appropriate wire gauge. These calculators provide accurate results and save time compared to manual calculations.

To use a wire size calculator, you need to input the relevant information about your circuit, such as the voltage and amperage rating (in this case, 40 AMPs). The calculator will then generate the recommended wire size based on the provided data.

It’s important to note that wire size calculators are valuable resources, but they should not replace the NEC guidelines. Always cross-reference the results obtained from the calculator with the NEC table to ensure compliance with the code.

Calculating the proper wire size for 40 AMP circuits requires understanding the NEC guidelines and utilizing wire size calculators. By following the NEC standards and using reliable calculators, you can ensure the safety and efficiency of your electrical installations.

Common Wire Sizes for 40 AMP Circuits

In this section, we will explore the recommended wire sizes for different applications in 40 AMP circuits. Understanding the appropriate wire size for your electrical to ensure safety and optimal performance. The American Wire Gauge (AWG) chart for 40 AMP circuits will also be provided to assist you in selecting the right wire size for your specific requirements.

Recommended Wire Sizes for Different Applications

When it comes to 40 AMP circuits, it is important to choose the correct wire size based on the application. The wire size directly affects the electrical current carrying capacity and determines the safety and efficiency of your electrical system. Here are the recommended wire sizes for common applications in 40 AMP circuits:

- Residential Use: For residential purposes such as powering appliances, air conditioners, or electric heaters, a 40 AMP circuit typically requires a wire size of 8 AWG. This wire size can handle the electrical load while minimizing voltage drop and ensuring safe operation.

- Commercial Use: In commercial settings where higher power demands may be present, it is often necessary to use larger wire sizes. For 40 AMP circuits in commercial applications, a wire size of 6 AWG is commonly recommended. This thicker wire allows for efficient power transmission and reduces the risk of overheating.

- Industrial Use: Industrial environments often have more demanding electrical requirements. When dealing with 40 AMP circuits in industrial settings, it is advisable to use a wire size of 4 AWG. This larger wire size can handle heavy machinery and equipment, ensuring a reliable power supply and minimizing the risk of electrical hazards.

It is important to note that these recommendations serve as general guidelines. Always consult with a qualified electrician or refer to the applicable electrical codes and regulations in your area to determine the appropriate wire size for your specific application.

AWG Chart for 40 AMP Circuits

Determining the right wire size for your 40 AMP circuit can be made easier by referring to the American Wire Gauge (AWG) chart. The AWG chart provides a standardized system for comparing wire sizes based on their diameter. Here is the AWG chart for 40 AMP circuits:

| AWG | Diameter (inches) | Diameter (mm) |

|---|---|---|

| 8 | 0.1285 | 3.264 |

| 6 | 0.162 | 4.115 |

| 4 | 0.2043 | 5.189 |

This table represents the most commonly used wire sizes for 40 AMP circuits. As the AWG number decreases, the wire diameter increases. By referencing this chart, you can easily identify the appropriate wire size based on your specific electrical needs.

Remember to always consider factors such as distance, voltage drop, and the specific requirements of your electrical system when selecting the wire size. Taking these factors into account will ensure the safe and efficient operation of your 40 AMP circuits.

In the next sections, we will delve into other important aspects related to 40 AMP circuits, providing you with valuable insights for your electrical projects. Stay tuned for more informative content on electrical wiring, safety precautions, and best practices.

Installation Tips for 40 AMP Wire Size

It is important to ensure proper insulation and protection when dealing with a 40 AMP wire size. In this section, we will discuss some installation tips that can help you achieve a safe and reliable electrical setup. We will cover proper insulation and protection, as well as wiring techniques and best practices to follow.

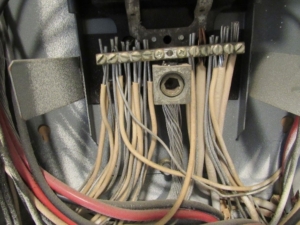

Proper Insulation and Protection

When working with a 40 AMP wire size, it is essential to prioritize insulation and protection to prevent any electrical hazards. Here are some tips to keep in mind:

- Choose the right wire: Select a wire that is suitable for 40 AMP applications. Look for wires that are labeled and rated for this specific amperage to ensure they can handle the current safely.

- Properly size conduits: Ensure that the conduits used are of the appropriate size for accommodating the 40 AMP wire. This will help prevent any damage to the wire during installation and make future maintenance easier.

- Use appropriate insulation: Make sure the wire is insulated with a material that meets electrical code requirements. The insulation should be able to withstand the voltage and current levels associated with a 40 AMP wire size.

- Protect against physical damage: Install the wire in a way that minimizes the risk of physical damage. This can be done by using conduit, raceway, or other protective methods to safeguard the wire from potential impacts, abrasion, or environmental factors.

Wiring Techniques and Best Practices

To ensure a successful installation with a 40 AMP wire size, follow proper wiring techniques and best practices. Here are some recommendations:

- Plan the wiring layout: Before starting the installation, carefully plan the wiring layout to ensure efficiency and minimize the length of wire runs. This will help reduce voltage drop and ensure optimal electrical performance.

- Properly terminate connections: Use appropriate connectors and terminals to ensure secure and reliable connections. Improperly terminated connections can lead to poor electrical contact, overheating, and potential hazards.

- Follow electrical codes: Adhere to local electrical codes and regulations when installing the 40 AMP wire. These codes are in place to ensure safety and compliance with industry standards. Familiarize yourself with the specific requirements for your location.

- Avoid overcrowding: Ensure that the wire is not overcrowded in junction boxes or panels. Overcrowding can lead to overheating and potentially compromise the integrity of the electrical system. Leave sufficient space for proper heat dissipation and ease of access.

- Perform thorough inspections: After the installation, conduct a thorough inspection to verify that everything is in proper working order. Look for any signs of damage, loose connections, or other issues that may need attention.

Following these installation tips for a 40 AMP wire size will help you create a safe and reliable electrical setup. Remember to prioritize proper insulation and protection, as well as adhere to recommended wiring techniques and best practices. By doing so, you can ensure the longevity and effectiveness of your electrical system.

Safety Precautions for 40 AMP Wire Size

When working with a 40 AMP wire size, it is important to prioritize safety in order to prevent any potential hazards or accidents. By following a few simple precautions, you can ensure a safe and efficient electrical installation. In this section, we will discuss two safety measures: avoiding overloading and overheating, as well as proper grounding and bonding.

Avoiding Overloading and Overheating

Overloading a wire can lead to overheating, which poses a significant fire risk. To prevent this, it is essential to understand the ampacity rating of the wire and ensure that it can handle the intended load. Here are some safety tips to keep in mind:

- Know the ampacity rating: Before using a 40 AMP wire size, familiarize yourself with its ampacity rating. This rating indicates the maximum amount of current the wire can safely carry. Exceeding this limit can cause the wire to overheat.

- Calculate the load: Determine the total electrical load that will be connected to the wire. This includes all the devices, appliances, or equipment that will be powered by the circuit. Make sure the load does not exceed the ampacity rating of the wire.

- Use appropriate circuit protection: Install the proper circuit breaker or fuse to protect the wire from overload. The circuit protection device should be sized according to the wire’s ampacity rating. This will help prevent excessive current from flowing through the wire and causing overheating.

- Avoid daisy-chaining: Do not connect multiple devices in a series using a single wire. This practice, known as daisy-chaining, can lead to overloading. Instead, use separate wires for each device or install additional circuits if necessary.

Proper Grounding and Bonding

Grounding and bonding are essential for electrical safety. They provide a path for electrical faults and surges to safely dissipate, reducing the risk of electric shock and equipment damage. Follow these guidelines to ensure proper grounding and bonding:

- Establish a grounding system: Install a grounding electrode system, which typically consists of grounding rods or plates, in compliance with local electrical codes. This system connects the electrical system to the earth, providing a safe path for electrical faults.

- Bond all metallic objects: Bonding involves connecting all metallic objects, such as electrical boxes, conduits, and appliances, together to create a common electrical reference point. This helps prevent potential differences and ensures that electrical faults are promptly detected and cleared.

- Use proper grounding conductors: Use appropriately sized grounding conductors to establish effective grounding. These conductors should be able to handle the fault current in the event of a fault, allowing it to flow safely to the ground.

- Regularly inspect grounding system: Periodically inspect and test the grounding system to ensure its integrity. This includes checking for loose connections, corrosion, or damage that could compromise its effectiveness.

By adhering to these safety precautions, you can minimize the risk of overloading, overheating, and electrical hazards when working with a 40 AMP wire size. Remember to always consult local electrical codes and regulations for specific guidelines and requirements in your area. Safety should always be the top priority to protect yourself and others from potential electrical dangers. Conclusion

In conclusion, selecting the appropriate wire size for a 40 AMP circuit to ensure efficient and safe electrical installations. The National Electrical Code (NEC) provides guidelines to help electricians and homeowners determine the correct wire gauge for specific amperage requirements.

When dealing with a 40 AMP circuit, the recommended wire size is typically 8 AWG (American Wire Gauge) for copper conductors. This gauge ensures that the wire can handle the current without overheating and causing potential hazards.

It is essential to consider factors such as wire length, temperature, and the type of insulation when choosing the right wire size for a 40 AMP circuit. By adhering to the NEC guidelines and consulting with a licensed electrician, you can ensure that the wire size is appropriate for your specific electrical needs.

Remember, using the correct wire size not only promotes optimal electrical performance but also minimizes the risk of electrical faults, fires, and damage to your electrical system.

In conclusion, always prioritize safety and follow the necessary guidelines when determining the wire size for a 40 AMP circuit. Doing so will help ensure a reliable and secure electrical setup for your residential or commercial space.