Sewer Pipe Lining: The Ultimate Guide to

Benefits, Types and Hiring a Professional

When it comes to home maintenance, certain tasks often go unnoticed until a problem arises. One such task is the upkeep of your home’s sewer system. Among the various methods available for maintaining and repairing sewer lines, sewer pipe lining has gained significant attention. It’s an efficient, cost-effective solution that can save homeowners the hassle of digging up their yards and the high costs of pipe replacement. This method involves creating a new, seamless pipe within the old, damaged one. It’s a less intrusive approach that can extend the life of your sewer system, saving you from potential headaches down the line.

What is Sewer Pipe Lining?

Sewer pipe lining is a highly effective solution for repairing and rehabilitating damaged or deteriorating sewer pipes. It involves the application of a durable lining material to the interior of existing pipes, creating a new, seamless pipe within the old one. This technique eliminates the need for costly and disruptive traditional pipe replacement methods.

Benefits of Sewer Pipe Lining

Sewer pipe lining offers numerous benefits that make it an attractive choice for property owners and municipalities alike. Here are some of the key advantages:

- Cost-Effective: Sewer pipe lining is often more cost-effective than traditional pipe replacement methods. By avoiding the need for excavation and pipe removal, it significantly reduces labor and material costs.

- Minimal Disruption: Unlike traditional pipe replacement, sewer pipe lining minimizes disruption to the surrounding area. It requires little to no excavation, which means less noise, dust, and inconvenience for residents or businesses in the vicinity.

- Time-Efficient: The process of sewer pipe lining is typically quicker than traditional pipe replacement. Since there is no need for extensive excavation and pipe removal, the overall project timeline is significantly reduced.

- Enhanced Durability: The lining material used in sewer pipe lining is highly durable and resistant to corrosion, cracks, and leaks. It creates a smooth, seamless inner surface that helps to prevent future blockages and maintain optimal flow capacity.

- Increased Flow Capacity: Over time, sewer pipes can accumulate debris and develop scaling or calcification, which restricts flow capacity. Sewer pipe lining restores the pipes to their original diameter, improving the flow and preventing future clogs.

- Long-Term Solution: By repairing and reinforcing existing pipes, sewer pipe lining provides a long-term solution that can extend the lifespan of the sewer system. It helps to prevent further deterioration and the need for frequent repairs or replacements.

- Environmentally Friendly: Sewer pipe lining is an environmentally friendly option compared to traditional pipe replacement methods. It reduces the amount of construction waste generated and minimizes disturbance to the surrounding ecosystem.

How Does Sewer Pipe Lining Work?

Sewer pipe lining is a highly effective method for repairing damaged or deteriorating sewer lines. It offers a cost-effective and long-lasting solution to restore the functionality of the pipes without the need for costly and disruptive excavation. This section will explain the step-by-step process of how sewer pipe lining works.

Step 1: Inspection and Preparation

The first step in sewer pipe lining is to thoroughly inspect the damaged pipe using advanced technology such as CCTV cameras. This allows the technicians to identify the extent and location of the damage. Once the inspection is complete, the pipe is cleaned using high-pressure water jetting to remove any debris or tree roots that may obstruct the lining process.

Step 2: Pipe Lining Material Preparation

After the pipe is cleaned, the next step is to prepare the pipe lining material. A flexible resin-saturated liner is measured and cut to the appropriate length. The liner is then saturated with epoxy resin, which acts as a bonding agent and creates a durable and watertight seal.

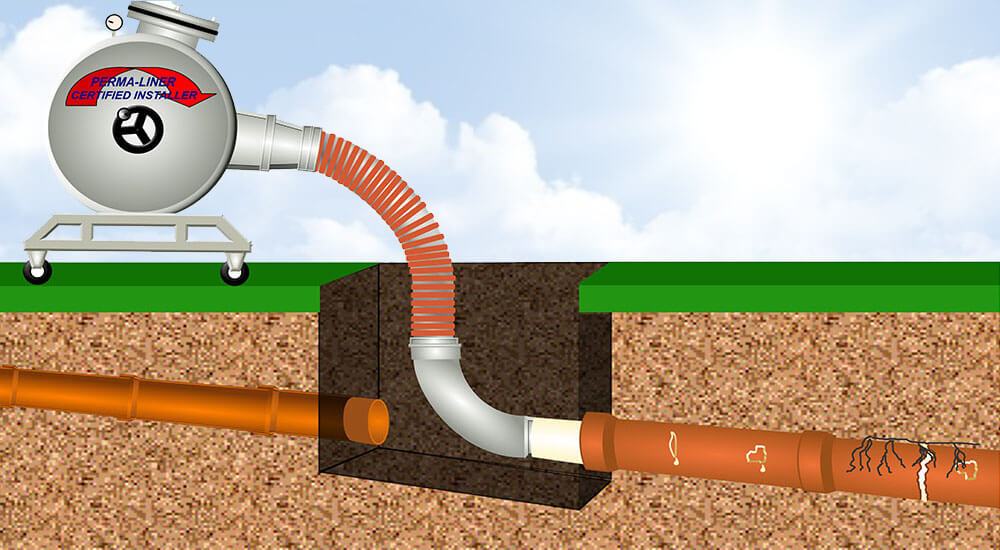

Step 3: Installation of the Liner

Once the lining material is prepared, it is inserted into the damaged pipe using specialized equipment. The liner is carefully positioned in the pipe to ensure proper alignment and coverage. In some cases, an inflatable bladder is inserted into the liner and inflated, pressing it against the walls of the damaged pipe. This helps to shape the liner and ensure a snug fit.

Step 4: Curing Process

Once the liner is in place, the curing process begins. This involves using hot water or steam to heat the epoxy resin, causing it to harden and create a structural lining within the existing pipe. The curing time may vary depending on the type of resin used, but it typically takes a few hours to complete.

Step 5: Final Inspection and Testing

After the curing process is complete, a final inspection is conducted to ensure the pipe lining has been properly installed. CCTV cameras are used once again to examine the newly lined pipe and verify its integrity. In addition, water or air pressure tests may be performed to check for any leaks or weaknesses in the lining.

Types of Sewer Pipe Lining

When it comes to repairing or replacing sewer pipes, there are several methods available in the market. In this section, we will explore three popular types of sewer pipe lining: Cured-in-Place Pipe (CIPP), Pull-in-Place (PIP), and Pipe Bursting. Each method offers its own unique advantages and considerations.

Cured-in-Place Pipe (CIPP)

Cured-in-Place Pipe (CIPP) is a trenchless sewer pipe lining technique that involves creating a new pipe within an existing damaged pipe. It is a popular choice due to its cost-effectiveness and minimal disruption to the surrounding area. The process starts with cleaning the existing pipe, followed by the insertion of a flexible liner saturated with a resin mixture. The liner is then inflated, and heat or UV light is used to cure the resin, forming a solid and durable new pipe inside the old one.

CIPP can be used for various pipe materials, including clay, concrete, and PVC. It is suitable for repairing pipes with cracks, leaks, or corrosion. The new pipe created by CIPP has a smooth interior, reducing the likelihood of future blockages and improving flow capacity. This method is particularly advantageous in urban areas where excavation can be challenging.

Pull-in-Place (PIP)

Pull-in-Place (PIP) is another trenchless sewer pipe lining technique that involves the installation of a new pipe by pulling it into the existing damaged pipe. This method is commonly used for smaller diameter pipes and is known for its efficiency and durability.

The process begins with the insertion of a liner impregnated with resin into the damaged pipe. A winch or hydraulic system is then used to pull the liner through the pipe, simultaneously inverting and curing the resin. The result is a structurally sound pipe that adheres tightly to the old pipe’s inner walls.

PIP is an excellent choice when dealing with pipes that have minor cracks, leaks, or root intrusions. It can also improve the hydraulic capacity of the pipe, reducing the risk of blockages. This method requires minimal excavation, making it a cost-effective and time-saving solution.

Pipe Bursting

Pipe Bursting is a trenchless sewer pipe lining method used primarily for replacing old and damaged pipes. Instead of rehabilitating the existing pipe, pipe bursting involves the complete removal of the old pipe and the installation of a new one in its place. This method is ideal for pipes that have suffered extensive damage, collapse, or deformation.

The process begins by creating two access pits at either end of the damaged pipe. A bursting head is then inserted into the old pipe, breaking it apart while simultaneously pulling the new pipe into position. The bursting head uses hydraulic force to fracture the old pipe, making way for the new pipe to be installed.

Pipe bursting is a reliable option for replacing pipes made of materials such as clay, cast iron, or concrete. It allows for the installation of pipes with larger diameters, increasing flow capacity and reducing the risk of future blockages. Although it requires more excavation than other trenchless methods, it is a cost-effective long-term solution.

Advantages of Sewer Pipe Lining

Sewer pipe lining is a revolutionary solution that offers numerous advantages over traditional methods of repairing or replacing damaged sewer pipes. In this section, we will explore the key benefits of sewer pipe lining, including minimal digging and disruption, cost-effectiveness, enhanced flow capacity, and durability and longevity.

Minimal Digging and Disruption

One of the major advantages of sewer pipe lining is the minimal amount of digging and disruption it requires. Unlike traditional methods that involve extensive excavation, sewer pipe lining utilizes advanced trenchless technology. This means that only a small access point needs to be created to insert the lining material into the existing pipe. As a result, there is minimal disruption to your property, landscaping, and daily activities. No more messy and time-consuming excavation work!

Cost-Effective Solution

Sewer pipe lining is not only an efficient but also a cost-effective solution. Traditional methods often involve significant costs associated with excavation, labor, and restoration of the affected area. With sewer pipe lining, these costs are drastically reduced. Since there is minimal digging required, the overall project cost is significantly lower. Additionally, the quick installation process saves you from incurring additional expenses for temporary accommodations or alternative sewer systems.

Enhanced Flow Capacity

Another advantage of sewer pipe lining is the enhanced flow capacity it provides. Over time, sewer pipes can accumulate debris, scale buildup, and tree root intrusion, causing reduced flow capacity and blockages. Sewer pipe lining involves the insertion of a specially designed resin-coated liner into the existing pipe. This liner restores the structural integrity of the pipe and smooths out any irregularities. As a result, the flow capacity is improved, allowing for efficient wastewater transportation and reducing the risk of clogs and backups.

Durability and Longevity

Sewer pipe lining offers exceptional durability and longevity. The lining material used is typically made of high-quality resin, which is resistant to corrosion, chemicals, and wear and tear. This means that the rehabilitated pipe is highly durable and can withstand the test of time. In fact, most sewer pipe lining installations come with warranties ranging from 50 to 100 years, providing you with long-term peace of mind. With minimal maintenance, you can enjoy a reliable sewer system for decades to come.

Signs You Need Sewer Pipe Lining

When it comes to the health and functionality of your plumbing system, it’s important to be aware of any potential issues that may arise. One such issue that can cause significant problems if left untreated is a damaged sewer pipe. In this section, we’ll explore the signs that indicate you may need sewer pipe lining. By identifying these signs early on, you can take proactive steps to address the issue before it becomes a major headache.

Frequent Drain Clogs

Have you noticed that your drains are constantly getting clogged? If you find yourself reaching for the plunger more often than not, it could be a sign that your sewer pipe is in need of lining. Over time, debris, grease, and other substances can build up on the inner walls of the pipe, resulting in frequent blockages. By opting for sewer pipe lining, you can restore the smooth flow of water through your pipes and prevent future clogs.

Sewage Backups

One of the most unpleasant signs that you may need sewer pipe lining is sewage backups. If you notice sewage coming back up through your drains or toilets, it’s clear that something is amiss with your sewer line. This can be a health hazard and should be addressed promptly. Sewer pipe lining can help repair any cracks or leaks in the pipe, preventing sewage from seeping into your home and causing further damage.

Foul Odors

Another telltale sign of a damaged sewer pipe is foul odors emanating from your drains. If you’re noticing a persistent, unpleasant smell coming from your sinks, toilets, or showers, it’s likely that your sewer line is compromised. This can occur due to cracks or breaks in the pipe, allowing sewage to leak into the surrounding area. Sewer pipe lining can effectively seal these cracks and eliminate the source of the foul odors, restoring a fresh and clean environment in your home.

Slow Draining Fixtures

Do you find that water is taking longer than usual to drain from your sinks, showers, or bathtubs? This could be an indication that your sewer pipe is in need of lining. Over time, the inner walls of the pipe can become rough and corroded, hindering the smooth flow of water. By opting for sewer pipe lining, you can create a smooth and seamless surface inside the pipe, allowing for faster drainage and preventing further issues down the line.

Hiring a Professional for Sewer Pipe Lining

When it comes to sewer pipe lining, it’s crucial to hire a professional who has the knowledge and expertise to get the job done right. Attempting to tackle this task on your own can lead to costly mistakes and potential damage to your sewer system. In this section, we will explore the steps you should take when hiring a professional for sewer pipe lining.

Research and Gather Recommendations

Before making a decision, it’s important to do your homework. Start by researching local professionals who specialize in sewer pipe lining. Look for companies with a strong reputation and a track record of high-quality work. To ensure you find the best option, reach out to friends, neighbors, or colleagues who have recently had their sewer pipes lined and ask for recommendations. Gathering information and recommendations from trusted sources will help you narrow down your choices.

Request Quotes and Assess Experience

Once you have a list of potential professionals, reach out to them and request quotes for the sewer pipe lining job. It’s essential to get multiple quotes to compare prices and services. Additionally, during this process, take the opportunity to assess the professional’s experience and expertise. Ask questions about their previous projects, the materials they use, and the techniques they employ. A knowledgeable and experienced professional will be able to answer your questions confidently and provide you with valuable insights.

Verify Licensing and Insurance

When hiring a professional for sewer pipe lining, it is crucial to verify that they have the necessary licensing and insurance. A licensed professional ensures that they have met the required industry standards and possess the knowledge and skills to perform the job correctly. Insurance, on the other hand, protects you from any liability in case of accidents or damages that may occur during the project. Before making a final decision, ask for proof of licensing and insurance to ensure you are working with a reputable and responsible professional.

Check Customer Reviews

One of the best ways to gauge the quality of a professional’s work is by checking customer reviews. Take the time to read online reviews and testimonials from previous clients. Look for patterns in their feedback, paying attention to both positive and negative aspects. This will give you a better understanding of the professional’s strengths and weaknesses. Keep in mind that no company is perfect, but pay close attention to any recurring issues that may be a cause for concern.

Conclusion

Sewer pipe lining is an effective and efficient solution for repairing damaged or deteriorating pipes. By using advanced technology and techniques, such as cured-in-place pipe lining, homeowners and businesses can avoid the disruption and high costs associated with traditional pipe replacement methods. Sewer pipe lining offers a long-lasting and reliable solution that can extend the lifespan of pipes, improve flow capacity, and prevent leaks and blockages. As a result, property owners can enjoy peace of mind knowing that their sewer system is functioning optimally. So, if you’re facing pipe issues, consider sewer pipe lining as a cost-effective and sustainable solution.