Can Duct Tape be Used as Electrical Tape?

Duct tape and electrical tape might look similar, but they’re made for different jobs. Can duct tape be used as electrical tape? The short answer is no. Duct tape isn’t safe for electrical tasks. It doesn’t have the same protective properties as electrical tape. But let’s dig deeper. We’ll explain why you shouldn’t use duct tape in place of electrical tape, and what could happen if you try.

Can Duct Tape be Used as Electrical Tape?

Electrical tape is an essential tool in any electrical project, providing insulation and protection for electrical wires and connections. However, in a pinch, you might find yourself wondering if duct tape can be a suitable substitute. In this section, we will explore the differences between duct tape and electrical tape, the risks of using duct tape as electrical tape, and the importance of proper usage.

Understanding the Purpose of Electrical Tape

Before delving into the topic, let’s first understand the purpose of electrical tape. Electrical tape is specifically designed to insulate and protect electrical connections, preventing short circuits and electrical shocks. It provides a reliable barrier against moisture, heat, and other potentially damaging factors, ensuring the safety and longevity of electrical installations.

Properties of Duct Tape

Duct tape, on the other hand, is a versatile adhesive tape that is known for its strength and durability. It is commonly used for a wide range of applications, such as fixing, sealing, and holding things together. However, it is important to note that duct tape is not designed for electrical purposes, and its properties differ significantly from those of electrical tape.

Differences Between Duct Tape and Electrical Tape

While both duct tape and electrical tape are adhesive tapes, they serve different purposes and possess distinct properties. Here are some key differences between the two:

- Adhesive Strength: Duct tape has a strong adhesive that is designed to bond to a variety of surfaces, making it ideal for heavy-duty applications. Electrical tape, on the other hand, has a less aggressive adhesive to allow for easy removal when necessary.

- Insulation Properties: Electrical tape is made from materials that provide excellent electrical insulation, protecting wires and connections from electrical currents. Duct tape lacks these specialized insulation properties and may not provide the same level of protection.

- Heat Resistance: Electrical tape is designed to withstand high temperatures generated by electrical currents, ensuring it does not melt or degrade. Duct tape, while durable, may not offer the same heat resistance and can potentially melt or become ineffective when exposed to excessive heat.

Potential Risks of Using Duct Tape as Electrical Tape

Using duct tape as a substitute for electrical tape can pose several risks:

- Electrical Hazards: Duct tape does not provide the same level of insulation as electrical tape. This can lead to electrical shocks or short circuits if electrical currents come into direct contact with the duct tape.

- Fire Hazard: Duct tape is not flame-retardant like electrical tape. In the event of a short circuit or electrical overload, the duct tape may catch fire, increasing the risk of property damage or injury.

Proper Usage and Importance of Electrical Tape

To ensure safety and compliance with electrical regulations, use electrical tape for its intended purpose. Proper usage of electrical tape includes:

- Insulation: Electrical tape should be tightly wrapped around exposed wires or connections to provide insulation and prevent contact with other conductive materials.

- Covering Exposed Areas: Electrical tape should be used to cover any exposed metal parts or terminals to avoid accidental contact and potential hazards.

- Securing Connections: Electrical tape can be used to secure and protect wire connections, preventing them from loosening or coming apart.

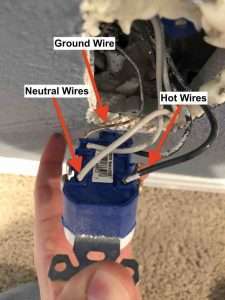

Working with electrical wires in a home can be dangerous and potentially lead to electrical shock if proper safety precautions are not followed. Electrical shocks occur when an electric current passes through a person’s body, which can cause injuries ranging from mild discomfort to severe burns, muscle contractions, and even death in extreme cases.

Avoid Electrical Shock

Here are some factors that can contribute to electrical shocks while working with electrical wires in a home:

1. Contact with live wires: If you come into direct contact with exposed live wires or if you accidentally touch a live wire while working on electrical circuits, you may experience an electrical shock.

2. Faulty equipment or wiring: Damaged or old electrical equipment, frayed wires, and faulty wiring increase the risk of electrical shock. Inspect the wiring and equipment for any signs of wear and tear before starting any work.

3. Lack of grounding: Grounding is a critical safety measure that helps prevent electrical shocks. If electrical systems are not properly grounded, a fault in the system may cause the electrical current to flow through unintended paths, leading to potential hazards.

4. Inadequate insulation: Proper insulation of wires is essential to prevent the current from leaking and causing shocks. Always ensure that electrical wires are well insulated and secured in their respective conduits.

5. Wet or damp conditions: Working with electrical equipment in wet or damp environments significantly increases the risk of electrical shock. Water is a good conductor of electricity and can lead to an electrical current finding alternative paths through the body.

To minimize the risk of electrical shock while working with electrical wires in a home, follow these safety guidelines:

1. Turn off the power: Always turn off the power at the main circuit breaker or fuse box before working on any electrical circuit or equipment. Use a voltage tester to confirm that there is no electricity flowing through the wires.

2. Use appropriate tools and equipment: Use insulated tools and wear personal protective equipment (PPE), such as insulated gloves and safety goggles, to protect yourself from potential electrical hazards.

3. Avoid working alone: Having someone nearby while working on electrical systems in case of an emergency. They can provide assistance or call for help if needed.

4. Learn about electrical systems: Before attempting any electrical work, it is essential to have a basic understanding of electrical systems and safety procedures. If you’re unsure about a particular task, it’s best to consult a qualified electrician.

5. Keep work areas dry: Avoid working on electrical equipment or circuits in wet or damp conditions. If the area is wet, make sure to dry it thoroughly before proceeding.

6. Follow local electrical codes: Familiarize yourself with local electrical codes and regulations to ensure that all work is done in compliance with safety standards.

Conclusion

In conclusion, while duct tape and electrical tape may seem similar, they are not interchangeable when it comes to electrical applications. Duct tape, although versatile and useful for many household tasks, is not designed or tested to meet the specific requirements of electrical insulation and safety.

Electrical tape, on the other hand, is specifically manufactured to provide insulation and protect electrical connections from moisture, heat, and other potential hazards. Its adhesive is formulated to withstand high temperatures and adhere securely to electrical wires and components.

Using duct tape as a substitute for electrical tape can lead to potential dangers, such as electrical shocks, short circuits, and even fires. Prioritize safety and always use the right materials for electrical work.

When it comes to electrical applications, it is always recommended to use electrical tape that meets the necessary safety standards. This ensures proper insulation and protection for your electrical connections, minimizing the risk of accidents or damage.

Remember, using the right tools and materials is essential for any task, especially when it involves electricity. So, next time you need to work on electrical projects, be sure to reach for the appropriate electrical tape and leave the duct tape for its intended purposes.