Bonding Gas Piping is Essential

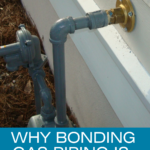

Bonding gas piping is an important safety precaution in any residential or commercial building. Bonding and grounding both ensure that electrical currents are not conducted through pipes, which can cause a fire hazard. Bonding is the process of connecting metal piping systems together with a conductor wire to create an equipotential bond.

This bond ensures that all portions of the system are at the same electrical potential, reducing the risk of an electrical shock. Gas lines should always be bonded at their point of connection to ensure a safe and efficient system. When bonding gas lines, it is important to use a bond that is designed and rated specifically for gas service.

This bond must also meet all applicable local and national code requirements. Properly installed bond wires provide a low-impedance path between two pieces of metal piping, helping to ensure maximum safety when working with natural gas systems. Additionally, bond wires should be inspected regularly and replaced if they become damaged or corroded in order to maintain optimal safety levels.

|

$41.00

|

|

Gas Pipe Bonding Code

In addition to providing a safe electrical connection, bonding and grounding of gas lines must also meet the requirements set forth in the National Fire Protection Association (NFPA) 54 Standard for the installation of gas appliances. This standard outlines various requirements for safely installing, operating, and maintaining gas appliances.

When it comes to proper bonding and grounding of gas lines, NFPA 54 requires that all metallic non-flexible piping connected to a natural or liquefied petroleum (LP) fuel system must be bonded to an approved ground source such as a cold water main or building steel frame. The same is true for flexible metal piping connected to any component containing flammable liquids or gases.

Frequently Asked Questions: Bonding Gas Pipe

How much does it cost to bond a gas line?

The cost of bonding a gas line will depend on how long the bonding wire needs to be, as well as the type and size of bonding material used. Generally, bonding materials for gas lines start at around $10 for basic copper wiring and can go up to several hundred dollars depending on the complexity of the job. Additionally, labor costs for bonding a gas line may range from $50-$150 per hour depending on your location. It is important to hire an experienced contractor who is knowledgeable about bonding and grounding requirements when installing or repairing any gas line in order to ensure maximum safety.

How to tell if a gas line is bonded?

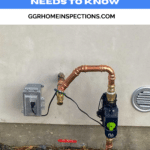

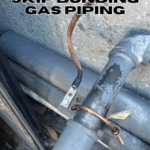

In order to tell if a gas line is bonded, you will need to visually inspect the bonding material. A bonding wire should be clearly visible and should be secured at both ends with bonding clamps that are connected to a ground source such as a cold water main or building steel frame. Additionally, bonding wires should be inspected regularly for any signs of corrosion or damage. If any issues are present, contact an experienced contractor immediately to repair or replace the bonding materials in order to ensure maximum safety when using natural gas systems.

What size wire to bond gas pipe?

The size of bonding wire used to bond gas pipe will depend on the type of bonding material being used as well as the length and diameter of the pipe. Generally, bonding materials for gas lines should be sized at least two sizes larger than the piping itself. For example, for a 3/4 inch copper pipe, a 1/0 AWG bonding wire would be appropriate. It is important to consult an experienced contractor or refer to local and national codes when selecting bonding materials in order to ensure maximum safety when using natural gas systems.

How do you complete bonding gas pipe to water pipe?

When bonding a gas pipe to a water pipe, it is important to use bonding clamps that are specifically designed for bonding gas pipes. These clamps should be connected securely to both the gas line and an approved ground source such as a cold water main or building steel frame in order to provide an adequate low impedance path. It is also important to inspect bonding wires regularly for any signs of corrosion or damage, and replace them if necessary in order to ensure optimal safety when using natural gas systems.

What size bonding clamp for bonding gas piping?

The size of bonding clamp used for bonding gas pipe will depend on the type of bonding material being used, as well as the length and diameter of the pipe.

|

$41.00

|

|

Summary: Bonding Gas Piping

Bonding gas piping is an essential task for ensuring the safest operation of residential and commercial buildings. Bonding wires provide a low-impedance path between metal pipes so that any static electricity buildup can be safely discharged from the system. The size of bonding material used will depend on the type of bonding material, as well as the length and diameter of the pipe.

It is important to hire experienced contractors with knowledge about bonding and grounding requirements when installing or repairing any gas line in order to ensure maximum safety. Additionally, bonding clamps should be specifically designed and rated for gas service, connected securely to both the gas pipe and an approved ground source such as a cold water main or building steel frame in order to provide an adequate low impedance path.

Regular inspection of bonding wires is also necessary in order to detect any signs of corrosion or damage; if any issues are present, contact an experienced contractor immediately to repair or replace bonding materials for safe operation of natural gas systems.

As always, if you have any questions please don’t hesitate to reach out to us. We would be happy to help clarify anything that may still be unclear.